Water is precious. Every day, industries face growing pressure to use less of it. Dry technology is emerging as a vital solutioncutting water use without compromising performance. This powerful innovation is transforming sectors such as energy, agriculture, and manufacturing. The dry technology is essential for building a sustainable and resilient future.

Dry Technology and Its Importance

Dry technology involves systems and processes that operate with minimal or no water. Traditional industrial methods often rely heavily on water for cooling, cleaning, or applying coatings. In contrast, dry alternatives use air, powders, or advanced materials to perform the same functions more sustainably. For instance, dry cooling systems utilize air to reduce heat, and powder coatings apply solid particles instead of liquid paint. These strategies not only save water but also lower energy use and reduce harmful emissions.

As water scarcity escalates, dry technology has become crucial. The United Nations warns that nearly two-thirds of the global population may face water shortages by 2025. Industries currently account for around 20% of the world’s freshwater use. Switching to dry processes helps reduce this burden, conserve resources, and ensure operational continuity during droughts.

Innovations in Dry Technology Across Industries

Dry cooling systems in power generation replace water with air or refrigerants to manage heat. These systems pass air over heat exchangers, eliminating the need for water-based cooling. A notable example is the Koeberg Nuclear Power Station in South Africa, which cut water use by over 90% by using dry cooling a major benefit in a drought stricken region.

Dry powder coating is another breakthrough. Instead of using solvent based paints, industries now use fine powders that are electrostatically applied and then cured with heat. This process eliminates solvents, cuts emissions, reduces waste, and produces durable finishes that resist corrosion.

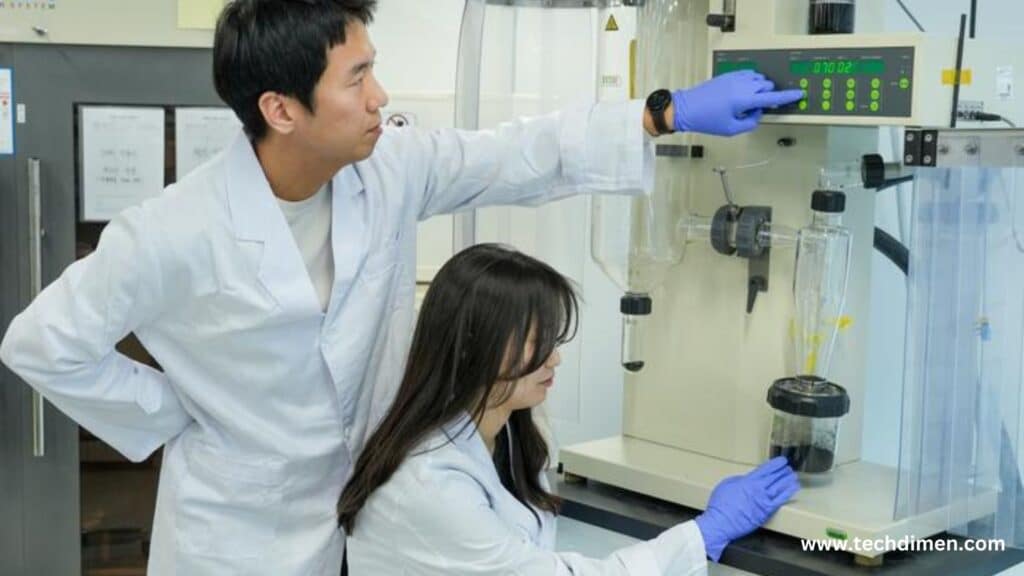

Manufacturing industries also benefit from dry processes such as dry granulation in pharmaceuticals, dry milling in food production, and solvent free manufacturing. These methods enhance product quality and safety while minimizing environmental impact.

In sectors requiring ultra clean environments, such as electronics and medical device manufacturing, dry cleaning and sterilization technologies use gases, plasma, or ultraviolet light. These systems avoid corrosion and reduce water and chemical use, meeting high cleanliness standards with minimal waste.

Leading Industries Adopting Dry Technology

Energy production is one of the largest industrial water users. Dry cooling helps plants operate in water-scarce environments without sacrificing efficiency. The Ivanpah Solar Electric Generating System in California, for example, saves roughly one billion gallons of water annually by using air instead of evaporative cooling.

Agriculture is also adapting. Dry methods such as air drying and dehydration preserve nutrients in food processing. Dry seed coatings add pest resistance without the need for water, and dry powder fertilizers improve soil application efficiency. These innovations make agriculture more sustainable and reduce dependency on water intensive methods.

Pharmaceuticals and chemicals benefit from dry processing by enhancing product stability, reducing contamination, and simplifying compliance with evolving digital transformation regulations. Less water use also means reduced microbial growth and extended product shelf-life.

Electronics manufacturing relies on dry etching and cleaning to protect components. These methods use plasma or chemical gases instead of wet baths, significantly cutting water and chemical consumption while achieving precision and quality.

Economic and Environmental Benefits

Dry technology significantly conserves freshwater. For example, dry cooling can reduce water use by up to 90% compared to traditional systems. This not only helps ecosystems but also supports water security in vulnerable communities.

Lower operational costs are another advantage. Companies save on water treatment, heating, and pumping. They also reduce energy consumption and avoid fines or restrictions from environmental regulators. The result is a leaner, more sustainable operation.

Meeting environmental regulations is easier with dry technology. Agencies like the U.S. Environmental Protection Agency (EPA) and the European Union require industries to reduce water use and pollution. Dry systems help meet these standards more efficiently and affordably.

Table: Comparison of Wet vs. Dry Technologies

| Feature | Wet Technology | Dry Technology |

|---|---|---|

| Water Consumption | High | Low to None |

| Energy Use | Higher (for water movement) | Lower (air-cooled or dry applied) |

| Maintenance Costs | Higher (scaling, corrosion) | Lower |

| Environmental Impact | Higher (discharge, emissions) | Lower (reduced waste and pollutants) |

| Regulatory Compliance | Challenging | Easier |

| Ideal Use Case | Water-rich environments | Water-scarce or regulated regions |

Challenges in Adopting Dry Technology

Despite its benefits, dry technology has some limitations. Dry cooling systems are slightly less efficient in heat transfer than wet systems, which can affect performance in extreme climates. Higher installation and retrofitting costs can also pose barriers, especially for existing infrastructure.

Some processes still require water due to its unique properties. In such cases, industries can reduce rather than eliminate water use, blending dry and wet methods for optimal results.

Innovations Driving the Future of Dry Technology

Hybrid systems that combine dry and wet methods are becoming more common. These systems adjust dynamically based on environmental conditions, reducing water use while maintaining performance.

Advances in materials science are also playing a role. New hydrophobic coatings and enhanced dry powders improve durability and efficiency in dry processes. These innovations make dry systems more effective and longer-lasting.

Automation and smart monitoring through Internet of Things (IoT) devices and AI-powered systems are streamlining dry technology. These tools can track performance, predict maintenance needs, and optimize settings in real time, ensuring maximum efficiency and uptime.

Implementing Dry Technology Effectively

Before adopting dry technology, industries must assess feasibility and return on investment. Factors include water savings, energy efficiency, regulatory compliance, and long term cost reductions. Working with experts ensures accurate modeling and informed decision making.

Choosing the right solution depends on industry needs, location, and budget. Power producers may prioritize dry cooling, while manufacturers might focus on dry coatings or cleaning methods. A tailored approach ensures the best outcome.

Collaboration with technology providers ensures smooth integration. Training, support, and expert consultation help businesses maximize the value of their dry systems and adapt as new innovations emerge.

FAQs

What Is Dry Technology?

Dry technology is an innovative method that replaces water-based processes with dry or low-moisture alternatives. It’s designed to conserve water, reduce waste, and enhance operational efficiency across various industries. Instead of using liquids to cool, clean, or process materials, dry systems rely on air, powders, or chemical reactions, making them more sustainable and often more cost-effective.

Where Is Dry Technology Used?

Dry technology shows up in a wide range of industries, from electronics and automotive to food processing, textiles, HVAC, and renewable energy. You’ll see it in dry etching for semiconductors, powder coatings for car parts, dry scrubbers in industrial exhaust systems, and air-cooled condensers in HVAC. Essentially, any field that values precision, efficiency, and sustainability can benefit from it.

How Does Dry Cooling Technology Work?

Dry cooling systems remove heat without using water. They rely on air to cool fluids or machinery through large heat exchangers. Instead of evaporating water like in wet cooling towers, these systems blow ambient air across coils or finned tubes to dissipate heat. This approach reduces water usage drastically and performs well in dry, arid climates.

Why Choose Dry Technology Over Traditional Methods?

The biggest advantage is water conservation. Dry technology eliminates the need for water in many industrial processes, reducing utility costs and environmental impact. It also minimizes corrosion, chemical scaling, and the need for wastewater treatment. Maintenance tends to be simpler, and systems last longer because there’s less wear from moisture and mineral buildup.

Is Dry Technology Always the Best Option?

Not necessarily. In extremely hot environments or large-scale facilities, wet systems might still provide higher cooling efficiency. However, when water use is limited or regulations are strict, dry technology offers a cleaner, more sustainable alternative. Choosing between dry and wet solutions depends on factors like budget, location, and performance requirements.

Which Industries Benefit Most from Dry Technology?

Industries that rely on precision and clean processes gain the most. In electronics, dry etching helps manufacturers create detailed microchips. In power generation, dry scrubbers remove pollutants without generating hazardous wastewater. Auto manufacturers use powder coatings to finish parts with minimal emissions. Even textile companies now use dry dyeing to save water and energy.

What Is Dry Etching in Electronics?

Dry etching is a crucial technique in semiconductor fabrication. It removes material from wafers using plasma or reactive gases instead of liquid acids. This method delivers extreme precision, allowing for the creation of tiny circuits and components. It also reduces chemical waste, lowers contamination risk, and enhances consistency in chip production.

How Does Dry Technology Help Reduce Pollution?

Dry pollution control systems like dry scrubbers treat industrial emissions without water. They inject dry sorbents—such as lime or sodium bicarbonate—into gas streams, neutralizing harmful compounds like sulfur dioxide or hydrogen chloride. The byproducts are solid and can be collected easily, reducing environmental risks and simplifying disposal.

Is Dry Technology a Sustainable Solution?

Yes, it plays a major role in sustainable industrial development. Dry systems reduce water usage, limit chemical runoff, and lower greenhouse gas emissions. They also tend to use less energy in the long run and support eco-certification efforts, helping companies meet environmental standards without compromising productivity.

Are There Any Disadvantages of Dry Technology?

Although efficient and eco-friendly, dry systems can come with higher upfront costs. They may also be less effective in extremely high-load or high-temperature situations. Additionally, transitioning from traditional wet systems to dry solutions may require reengineering or staff retraining, which could add to implementation time and cost.

How Is Dry Cleaning Different from Standard Laundry?

Dry cleaning uses chemical solvents to clean fabrics without water. Modern systems often use environmentally friendly solvents like liquid CO₂ or silicone-based compounds. These methods are gentler on delicate materials and better at removing oil-based stains. They also create fewer emissions compared to traditional solvent-based systems.

What Role Does Dry Technology Play in HVAC?

In HVAC systems, dry technology appears in air-cooled condensers and desiccant dehumidifiers. These components control temperature and humidity without using water. They’re especially valuable in places where moisture control is critical or where water conservation is a concern. Plus, they reduce maintenance by eliminating issues like scale buildup or mold growth.

How Does a Dry Scrubber Work in Industrial Settings?

A dry scrubber treats polluted air by injecting dry chemicals into the exhaust stream. These react with harmful gases like sulfur dioxide and convert them into solid byproducts. The solids are then captured by filters or cyclones, allowing clean air to exit while minimizing environmental waste and water usage.

What Is Dry Powder Coating and Why Is It Effective?

Dry powder coating involves applying electrically charged powder particles to a surface, which are then baked to form a smooth, protective finish. Unlike liquid paint, this process doesn’t require solvents, so it emits fewer volatile organic compounds (VOCs). It also creates less overspray waste and results in highly durable coatings.

Is Dry Technology Energy-Efficient?

Yes, dry systems can significantly reduce energy consumption. Since they don’t need to heat, pump, or treat water, they often operate at lower energy costs. Their simple design and reduced maintenance needs also lead to long-term savings. For businesses focused on sustainability and efficiency, dry technology is a smart investment.

Final Thoughts

Dry technology is not just an alternative it is fast becoming a necessity in modern industrial operations. Its capacity to save water, lower emissions, and streamline processes aligns perfectly with the global shift toward sustainability and smart innovation. Businesses willing to invest in this future-proof strategy stand to gain both economically and reputationally.

Embracing dry technology today is a powerful move toward a greener, more efficient tomorrow. From energy and agriculture to electronics and pharmaceuticals, every sector has something to gain. With continuous advancements and broader adoption, dry technology will undoubtedly play a critical role in reshaping the industrial landscape for the better.

Jhon AJS is a tech enthusiast and author at Tech Dimen, where he explores the latest trends in technology and TV dimensions. With a passion for simplifying complex topics, Jhon aims to make tech accessible and engaging for readers of all levels.